Introduction: The Technological Leader in the Field of Amphibious Equipment

According to the latest data from Markets and Research, the global amphibious construction equipment market surpassed $2.12 billion in 2023, with Southeast Asia and Africa’s emerging markets growing at a rate of 8.3%. As Chinese largest amphibious excavator solution provider, River Heavy Industry has addressed the industry challenges of “shallow water machine sinking” and “deep water instability” in 47 countries with its innovative modular buoyancy system. Our 20 years of practical experience with pontoon technology has set benchmarks for our equipment in extreme environments like the Mekong Delta and the Congo River Basin!

I. Poor buoyancy control? Two major pain points fully resolved! The buoyancy control revolution: Precisely solving two key scenarios.

1. Shallow Water/Marsh Operations – River’s Main Pontoon Undercarriage Configuration

Traditional Pain Points of Amphibious Undercarriage: Heavy machines self-weight sink, clumsy movement, low efficiency.

River Solution:

- Lightweight design: Using high-strength alloy pontoons, the weight is reduced by 30%, making movement in muddy areas more flexible and reducing fuel consumption by 15%!

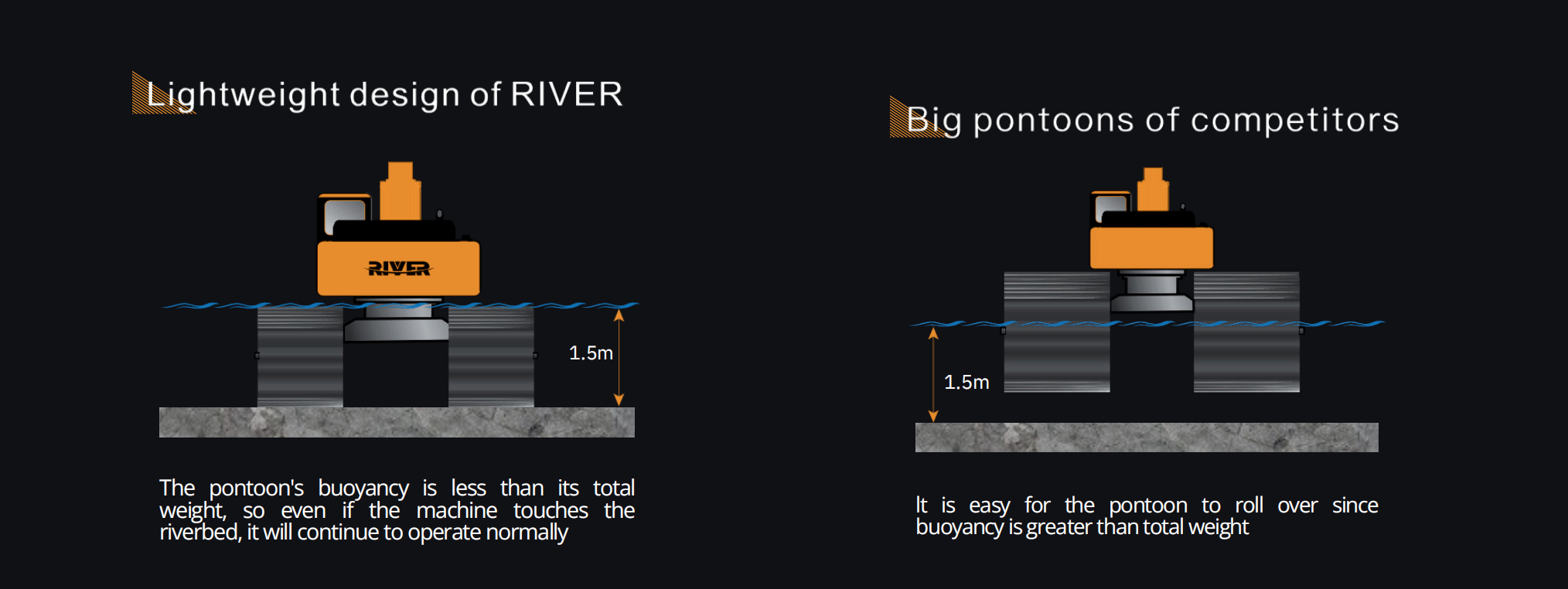

- Main pontoon bottom-touch operation: When equipped with the main pontoon, the total buoyancy of the pontoon undercarriage is less than the total weight of the amphibious excavator, allowing direct bottom contact in shallow water and marshes up to 1.5 meters or the height of main pontoons, providing stability comparable to land operations!

2. Deep-Water Operations – Side Pontoons with Positioning Piles’s Configuration of River

Traditional issue of operating amphibious excavator: Insufficient buoyancy leads to easy tipping, and if the amphibious excavator comes with a standard arm, operation would be limited.

River Solution:

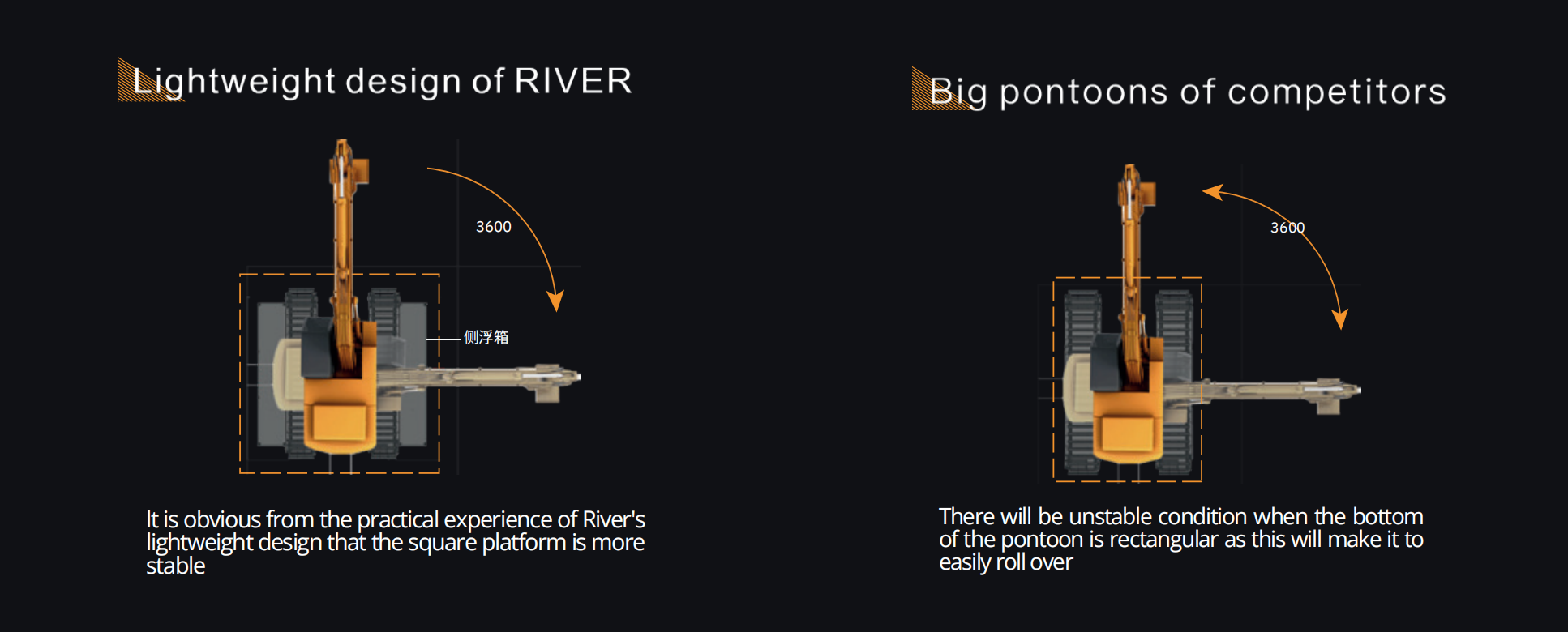

- Main pontoon + side pontoon combination: When looking down, it looks like a “square platform”, increasing wind and wave resistance by 50%, with 360° rotation as steady as Mount Tai!

- Extended and enlarged side pontoon design: Expands the operational radius in deep water, allowing the standard arm to easily dig deeper and reach farther.

- Positioning pile design: The side pontoons are equipped with hydraulic positioning piles, which can be driven into the mud in depths of 4-5 meters, making dredging operations as steady as a rock!

Our amphibious pontoon undercarriage design can be summed up in one sentence: as flexible as building blocks. Generally, an amphibious excavator (equipped with a main pontoon undercarriage) can adapt to all shallow water and marsh work environments. In such conditions, it can touch the bottom without sinking, with the use of lightweight, higher-strength materials for added safety and stability, resulting in a significant boost in efficiency. In deep water areas, the positioning pile-type side pontoons can be quickly installed in just one hour, instantly transforming it into a “water platform” that resists tipping, ensuring safe and stable operations.

II.Global Witness: A Record of Multinational Project

Case 1: Vietnam River Dredging

Project Background: Ho Chi Minh City’s key waterway widening project, with an average tidal difference of 2.3 meters, and a riverbed containing up to 4 meters of fluid mud.

Traditional Challenges: Local contractors used Japanese-standard amphibious equipment, which encountered multiple overturn risks during high tide periods, with an average monthly maintenance cost exceeding $80,000.

River Solution:

- Custom dual-mode buoyancy system: The main pontoon was designed with high-strength, lightweight materials (reducing weight by 35%) and paired with positioning side pontoon.

- Intelligent weight adjustment: A hydraulic sensor system automatically balances tidal loads.

Results Comparison:

- Dredging efficiency increased from 120m³/day to 310m³/day.

- Project duration shortened by 42 days, saving the owner $870,000 in penalty fees.

The Vietnamese Ministry of Transport commented: “Chinese technology has brought the delta project into the 24-hour operational era.”

Case 2: Indonesia Mangrove Restoration Project

Ecological Challenge: A UNDP-funded project that required operations in waters with an average depth of 3.8 meters and wave heights of 1.2 meters.

Equipment Crisis: A European brand amphibious excavator sank due to buoyancy calculation errors, resulting in a $1.9 million loss.

River Solution:

- 3D Fluid Simulation: Designed an X-shaped pontoon with a central support based on local monsoon data.

- Patent-Pending Positioning Pile System: 6-meter hydraulic piles penetrated the seabed’s hard layer, with GPS positioning accuracy of less than 5 cm.

Construction Results:

- Completed 34 hectares of mangrove substrate preparation, 11 weeks ahead of the original schedule.

- Equipment maintained a tilt of less than 0.8° during level 6 winds and waves and was listed by UNDP as “Recommended Amphibious Equipment for coastal ecological projects.”

- Project Director Dr. Wahyudi expressed special thanks: “This is our only large-scale wetland project with zero accidents in the past five years.”

III. Why Clients Choose RIVER?

- 20 Years of Practical Experience: Deeply adapted engineering DNA. We are not just amphibious equipment suppliers, but also the contractor behind over 1,000 land-water projects completed.

- Full Brand Coverage: Supporting mainstream brands like Caterpillar, SANY, XCMG, with full coverage of 5-50 ton models.

- Customizable Support: Complex terrain? Tight schedule? We can customize pontoon size and layout based on site conditions & project requirements (such as tides and mud thickness)!

IV. Act Now: Unlock Your Global Project Key

River Heavy Industry offers full-chain support, from equipment modification to construction solutions. Consult now to obtain:

√ Free access to the “Land-Water Engineering Buoyancy Calculation Manual”

√ Application guidance for government subsidies on equipment modifications (available for ASEAN countries)

River Heavy Industry, with twenty years of practical expertise, ensures that every piece of equipment becomes your Noah’s Ark in conquering all kinds of dredging conditions!

Click to inquire and get your customized river dredging solution for free.