HYDRAULIC DREDGE PUMP

Hydraulic Cutter Suction Pump

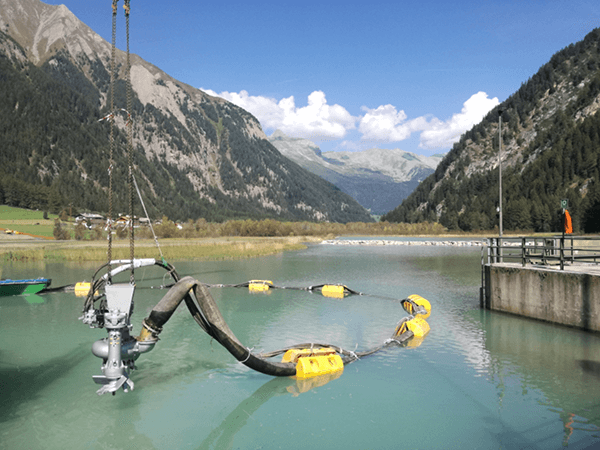

The hydraulic cutter suction pump, branded as RIVER, is an essential auxiliary device alongside amphibious excavators in dredging operations. This innovative hydraulic dredge pump is specifically designed for environments where water, silt, and mortar prevail, conditions that typically hinder excavation efforts and complicate vehicle transportation. Integrating the RIVER’s dredging pump into your operations can significantly enhance work efficiency, overcoming the challenges posed by less conducive dredging environments. The RIVER’s excavtors with hydraulic dredge pump transforms complex tasks into streamlined processes, ensuring your projects proceed smoothly and effectively.

High Effecient Hydraulic Dredge Pumps For Sale

Hydraulic cutter suction pump is a kind of dredging attachment that is mounted to an excavator as an auxiliary device, which is made of high-chromium alloy material specially used for slag, and the motor is a military quantitative plunger motor.

Features of Hydraulic Dredge Pump

- Auxiliary Device for Amphibious Excavators: Excavator dredge pump enhances dredging operations.

- Effective in Challenging Conditions: Performs well in waterlogged, silty areas where traditional excavation and transportation are difficult.

- High-Quality Materials: Made from high-chromium alloy, ensuring long-lasting performance and resistance to wear..

- Advanced Motor: Equipped with a military-grade quantitative plunger motor.

- Advanced Structure: Designed for optimal performance and efficiency.

- High Efficiency: Greatly improves work efficiency in dredging operations.

Specifications of Hydraulic Dredge Pump

| Suitable Model | Hydraulic Motor Part | Pump Part | ||||||

| Displacement(CC) | Pressure(Mpa) | Flow(L/min) | Speed(rpm) | Water outlet(mm) | Flow(m³/h) | Head(m) | Graininess(mm) | |

| 25-30 ton Excavator | 160 | 27 | 240 | 1000 | 300 | 660 | 30 | 50 |

| 18-23 ton Excavator | 112 | 27.5 | 168 | 1000 | 200 | 400 | 30 | 40 |

| 13-15 ton Excavator | 50 | 25 | 75 | 1000 | 150 | 150 | 22 | 30 |

| 6-9 ton Excavator | 32 | 25 | 48 | 1000 | 100 | 130 | 15 | 25 |

Benefits of Using a Hydraulic Dredging Pump in Dredging Projects

- River and Lake Dredging: Clearing sediments to maintain navigable waterways.

- Environmental Restoration: Removing contaminated sediments to restore and protect aquatic ecosystems.

- Flood Control: Dredging channels and reservoirs to improve water flow and prevent flooding.

- Construction Projects: Preparing underwater foundations for structures such as bridges, piers, and docks.

- Mining Operations: Extracting valuable minerals and materials from underwater deposits.

- Extended Amphibious Excavator Capability: Enhances the functionality and versatility of amphibious excavators in various dredging projects.

How an Amphibious Excavator with Hydraulic Dredge Pump Works?

Hydraulic Dredge Pump Applications and Uses

Ports, river channels, lakes dredging and maintenance

- Excavators with hydraulic dredging pumps are used to deepen and maintain port channels to accommodate larger ships.

- Essential for removing accumulated sediment in river channels and lakes to prevent flooding and improve water flow.

- Keeping docking areas clear of debris and maintaining sufficient depth for safe vessel operation.

Sand, mud dredging, sea reclaim project

- Excavators are instrumental in reclaiming land from the sea by dredging and relocating sand and mud.

- Used to replenish eroded beaches by dredging sand from the seabed and depositing it on the shore.

- Creating barriers and protective layers to shield coastal areas from erosion and storms.

Absorbing High-Concentration Tailings, Waste Residue, and Iron Slag

- Removing tailings and waste residue from mining sites to manage waste and recover valuable minerals.

- Handling and disposing of iron slag and other by-products generated during the smelting process.

- Dredging tailings ponds to manage waste materials and prevent environmental contamination.

Slag Removal of Iron Ore, Tailings Pond, Concentrator, and Other Mines

- Excavators with hydraulic dredging pumps are used in concentrators to remove slag and other waste materials during ore processing.

- Efficiently managing and removing waste materials from mining sites to ensure environmental compliance.

- Assisting in the rehabilitation of mined areas by removing waste and preparing the site for reclamation.

Sand Pumping, Gold Mining

- Excavators are used to pump sand from riverbeds and coastal areas for construction and industrial uses.

- Essential in placer mining operations to extract gold from alluvial deposits using hydraulic pumps to transport slurry.

- Extracting and transporting aggregates such as sand and gravel for construction projects.

Lake development, wetland park construction, river dredging

- Removing sediment and debris from rivers and lakes to restore natural habitats and improve water quality.

- Constructing and maintaining wetland parks for biodiversity conservation and recreational purposes.

- Dredging rivers to increase capacity and prevent flooding in surrounding areas.

China Hydraulic Dredge Pump Factory – RIVER MACHINERY

Dredging is one of the most vital processes taken into use to remove the deposits percolated underwater to clear the water pathway for ships to pass and create adequate space to construct important bridges, dams, and dykes and weed out the slit, intoxicants, and pollutants from the bottom of the water. For this process, you need to choose the right models of dredge pumps and advanced models of dredge machines that you can get right to your address in an insecure way.

RIVER MACHINERY have the latest models of dredging pumps and cutter suction pumps that are used as auxiliary devices of the amphibious excavator to perform dredging operations, where there is more water, silt, and mortar that are less conducive to excavation and inconvenient for vehicle transportation that greatly improves the work efficiency.

Choosing the right type of pump and dredge machine is important. We offer you the best hydraulic dredge pump for heavy-duty dredging, which are easy to use and come with several added features. Choose the right models, go through the details, and place your order. Each one is packed securely and delivered on time.

Feel free to contact our sales for assistance!

Hydraulic Dredge Pump Maintenance Tips

- Regular Inspection: Conduct routine inspections of your hydraulic dredge pump. Look for signs of wear and tear, corrosion, and any loose or damaged components. Replace them as needed to avoid unexpected failures

- Clean the Pump: After each use, thoroughly clean the pump to remove any debris, sediment, or materials that may have accumulated. This prevents clogs and ensures smooth operation.

- Monitor Performance: Keep an eye on the pump’s performance metrics, such as pressure and flow rates. Any significant deviations from the normal range may indicate underlying issues that need to be addressed.

- Follow Manufacturer’s Guidelines: Always adhere to the maintenance guidelines provided by the pump manufacturer. This includes service intervals, recommended parts, and procedures to ensure proper upkeep of the equipment.

- Store Properly: When not in use, store the dredge pump in a clean, dry, and sheltered location. Protecting the pump from harsh environmental conditions can extend its lifespan.

- Train Operators: Ensure that all operators are properly trained on the correct use and maintenance of the hydraulic dredge pump. Proper handling and operation can prevent unnecessary wear and damage.

FAQ

FIND YOUR RIGHT SOLUTION FROM CHINA SUPPLIER

RIVER MACHINERY prioritizeS delivering top-notch hydraulic dredge pumps for amphibious equipments. For inquiries or to discuss your specific needs, kindly fill out the form below. Your satisfaction is our global priority, and we ensure swift responses to clients worldwide. We look forward to connecting with you soon!