High Quality Amphibious Undercarriage For Sale

Features of Versatility Amphibious Undercarriage

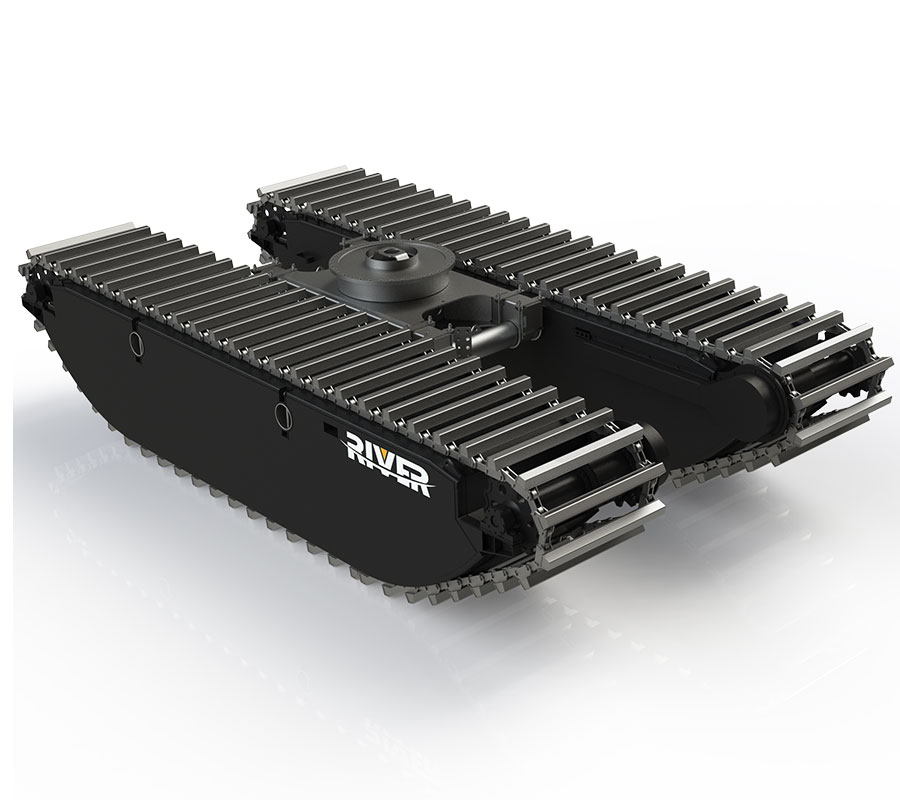

- Pontoons Buoyant: Equipped with specially designed pontoons for stability and flotation on water surfaces.

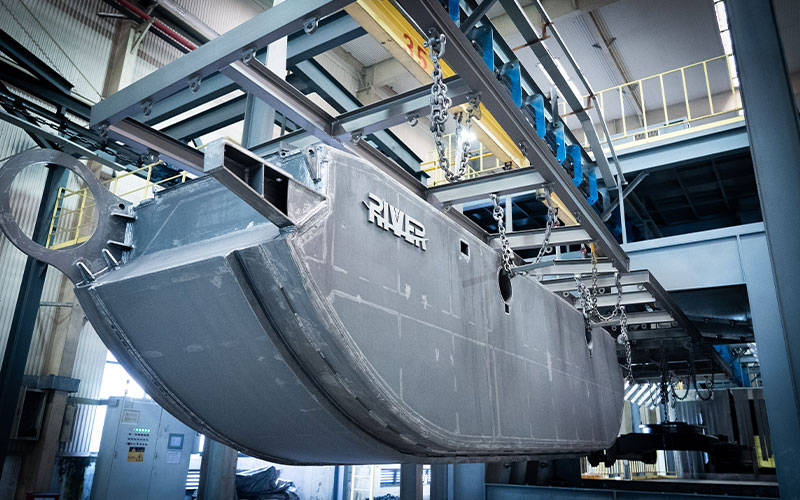

- Durable Construction: Built with robust materials that resist wear and corrosion for longevity in harsh environments.

- Enhanced Mobility: Allows amphibious excavators to transition seamlessly between land and aquatic settings, improving access to difficult terrains.

- Low Ground Pressure: The track shoes of amphibious excavators is more wider, which designed to exert minimal pressure on the ground, protecting sensitive ecosystems during operations.

- Durable amphibious undercarriages: HG785D High-Grade Steel used for its exceptional strength-to-weight ratio, high-grade steel ensures the pontoon undercarriage’s structural integrity and durability.

- Protective Coatings and Paints: We apply superior epoxy zinc-rich paint to our amphibious undercarriages, boosting their strength and lifespan against extreme conditions through corrosion and abrasion-resistant coatings, protecting it from harsh elements and extending its service life.

Contact us today!

Versatility Amphibious Undercarriage For All Terrain Excavation

Specifications of Versatility Amphibious Undercarriage

| Description | UNIT | CODE | RS80-A2 | RS150-A2 | RS215-A2 | RS250-A2 | RS300-A5 | RS350-A5 | RS400-A6 |

| Length of pontoon | mm | A | 5960 | 7000 | 8140 | 8500 | 9100 | 9500 | 10000 |

| Width of pontoon | mm | B | 1000 | 1250 | 1500 | 1600 | 1600 | 1600 | 1700 |

| Height of pontoon | mm | C | 1300 | 1600 | 1800 | 1900 | 1900 | 1900 | 2000 |

| Overall width | mm | D | 3000 | 3650 | 4490 | 4800 | 5000 | 5000 | 5200 |

| Minimum ground clearance | mm | E | 865 | 1064 | 1209 | 1303 | 1300 | 1300 | 1450 |

| Grounding length of pontoon | mm | F | 3350 | 3389 | 4324 | 3695 | 4980 | 4980 | 6100 |

| Total weight of pontoon | T | 6.4 | 11 | 15.2 | 17.9 | 20.6 | 21.8 | 27 |

How Amphibious Undercarriage Excavators Work in Shallow Water?

Applications of Versatility Amphibious Undercarriage

- Wetland Restoration and Management: They are instrumental in restoration projects, allowing for the removal of invasive species and the planting of native vegetation without harming the delicate ecosystem.

- Flood Control and Management: Amphibious undercarriages are crucial in building and maintaining levees, dikes, and other flood control structures, especially in areas that are partially submerged.

- Environmental Cleanup: They play a vital role in cleaning oil spills and managing waste in waterlogged areas, ensuring minimal environmental impact.

- Infrastructure Construction: These undercarriages are utilized in constructing bridges, docks, and other structures in shallow waters or swampy areas, where traditional machinery cannot operate.

- Mining and Resource Extraction: In peat and marshland mining operations, amphibious undercarriages enable the extraction of resources with minimal disruption to the surrounding environment.

- Search and Rescue Operations: Their ability to navigate through waterlogged and marshy terrains makes them indispensable for search and rescue operations in disaster-stricken areas.

- Dredging Activities: Used for dredging operations in rivers, lakes, and shallow coastal areas, helping to maintain waterways and prevent flooding.

Selected Materials for Track Shoes

Aluminum alloy track shoes: Selected for its light weight and corrosion resistance, aluminum is often used in parts of the undercarriage that benefit from reduced weight without compromising strength.

UHMWPE track shoes/pad: UHMWPE track pad is made of high performance plastic material -Ultra high molecular weight polyethylene (UHMW-PE). These materials are used for making the track shoes of amphibious undercarriage, offering buoyancy along with resistance to impact, abrasion, and water infiltration.

The two materials mentioned have their respective pros and cons. The advantage of these materials is their lighter weight. However, the drawbacks include higher cost and increased susceptibility to wear and tear. Should you choose to utilize this material for track shoes, we offer customization services. Our standard pontoon undercarriage features track shoes made of steel, which enjoys greater popularity in the Chinese market.

Related Amphibious Undercarriage Attachments

Spuds/Positioning Piles

High Quality Hydraulic Spud Barge For [...]

Additional Side Pontoons

High Quality Additional Side Pontoons For [...]

FIND YOUR RIGHT SOLUTION WITH RIVER HEAVY INDUSTRY

At RIVER, we prioritize delivering top-notch amphibious excavators and pontoon uncercarriage attachments. For inquiries or to discuss your specific needs, kindly fill out the form below. Your satisfaction is our global priority, and we ensure swift responses to clients worldwide. We look forward to connecting with you soon!