WHAT SIZE OF AMPHIBIOUS EXCAVATOR DO I NEED?

1. What Is An Amphibious Excavator?

Amphibious excavators are also a type of heavy machinery for construction machinery. They have the incomparable advantages and particularities of traditional crawlers or wheeled excavators and can reach some areas that traditional excavators cannot reach or are even relatively dangerous. Therefore, it is very important to choose a suitable and high-quality amphibious excavator, and a suitable type and size of floating pontoon undercarriage can make your construction efficiency more efficient;

Amphibious excavators, also known as wetland buggies, swamp buggies, or floating excavators, are widely used in fields such as silt, shallow water, lakes, swamps, seashores, and even underground mines, and play a pivotal constructive function in the field of construction machinery.

2. What Are The Uses Of Amphibious Excavators?

River dredging and channel deepening;

natural environment restoration;

reclaiming land around the lake;

Ditch management;

port construction;

fish pond management;

Underground sewage well cleaning;

coastline development;

highway construction;

Flood fighting and emergency rescue;

Oil and gas pipeline installation;

PV(photovoltaic power generation);

3. What Are The Characteristics Of The Amphibious Excavators Produced By River?

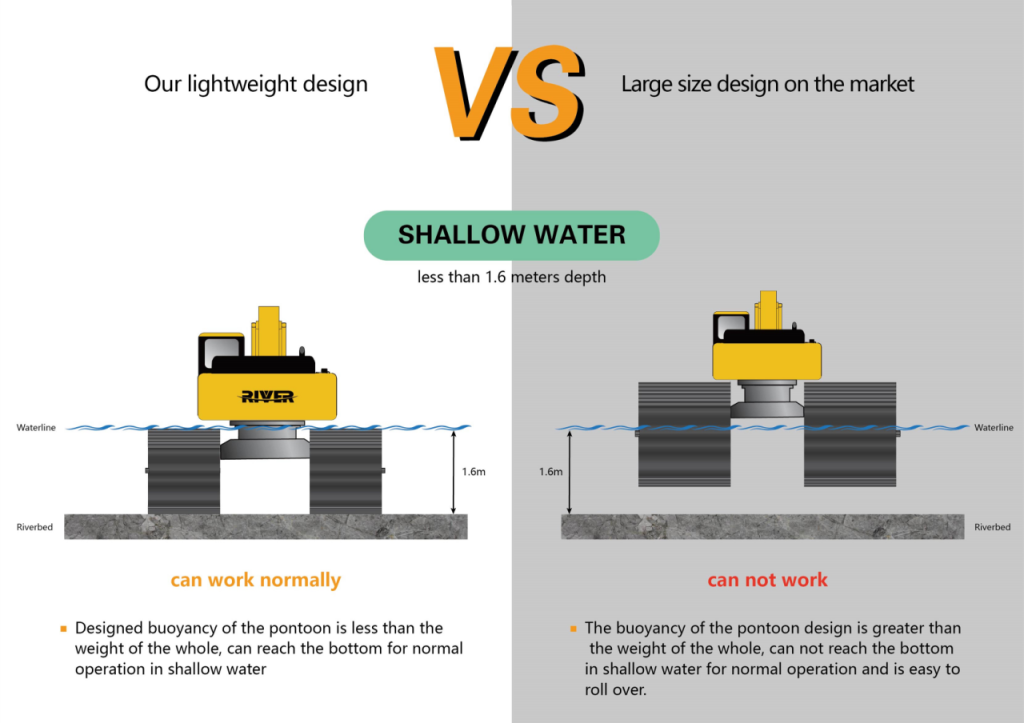

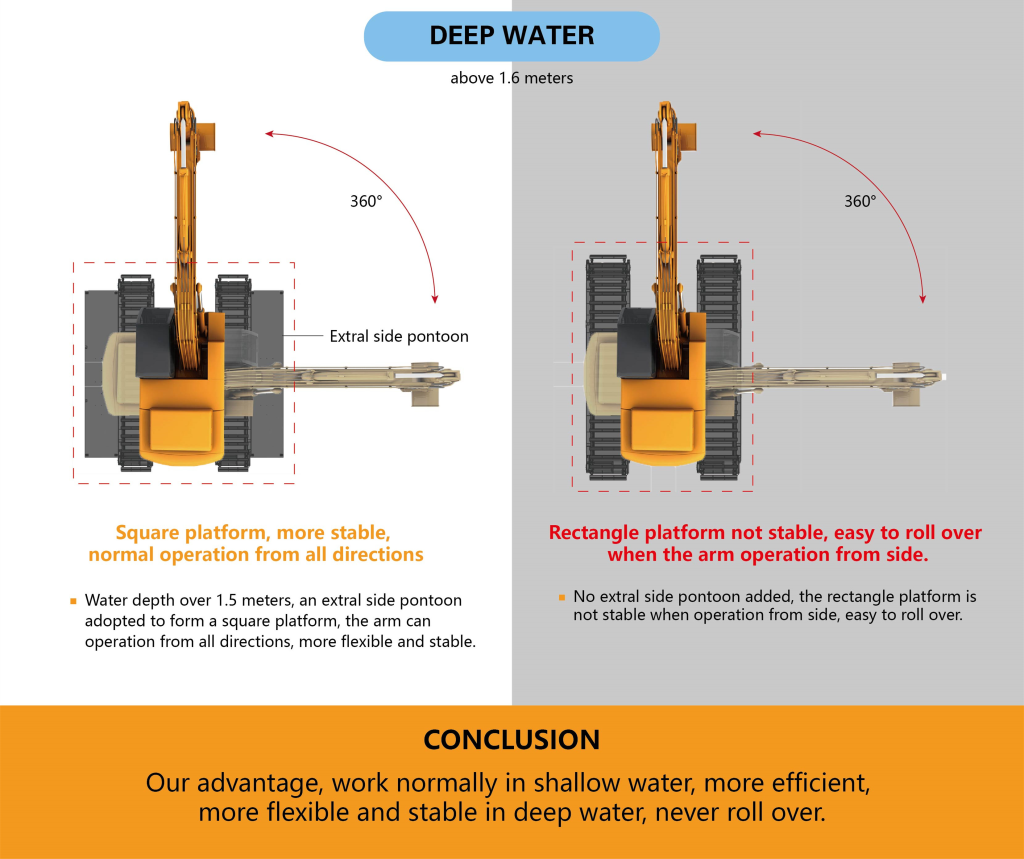

3.1 Lightweight: in general, the buoyancy of the floating pontoon we designed is less than the weight of the whole vehicle(amphibious excavator), which makes the amphibious excavator not float when working in shallow or deep water, so that it’s more stable during work; if the equipment needs to be carried out construction work in deep water environment, it is necessary to add side floating pontoon or positioning pile device;

3.2 Durability: the internal skeleton of the floating/side pontoon is meticulous, making the entire floating pontoon structure more stable, and the overall structure of the floating pontoon is still intact even after a few years of use; the track shoe of the amphibious excavator is made of HG785 high-strength steel plate, and the internal reinforcement plate technology is adopted to ensure the strength of track shoes is higher and not easy to deform; in addition, we also add wear strips on the contact surface between the floating pontoon and the roller to effectively prevent the wear of the pontoon undercarriage caused by long time touch with the sprocket;

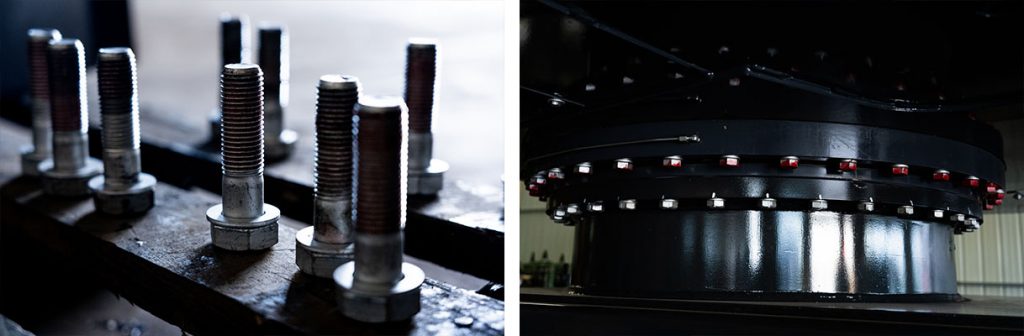

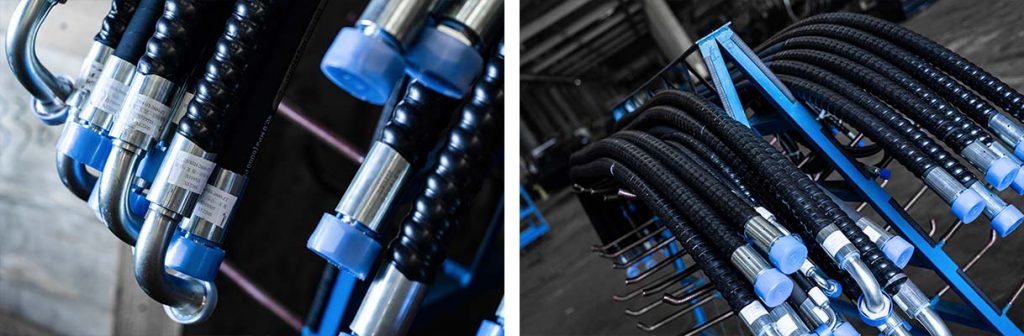

3.3 Reliability: the screws installed on the amphibious undercarriage are treated with the Dacromet process, which is not easy to rust and is more durable; the hydraulic oil pipes and joints are from high-quality imported brands, and the oil pipes are made of 4-layer pipe technology, which is durable and not easy to burst or crack;

4. How To Choose The Appropriate Model And Size Of Amphibious Excavators? What Are The Primary Selection Considerations Of Amphibious Excavator Models&Sizes?

4.1 Engineering Scene

Transportation restrictions: Check whether the trails on the way to the construction site allow the amphibious excavators to be driven in after the swamp buggy is installed;

Amphibious excavator pontoon and overall transportation dimensions, such as the size of the amphibious excavator listed on the page cannot meet the construction needs, we can reasonably customize the pontoon undercarriage size according to your construction situation; of course, if the transportation site is limited, the extendable amphibious excavator will be a good choice. For example, for a 20-ton amphibious excavator, the normal overall undercarriage width is 4.5 meters. After it is designed as an extendable pontoon, its width can be controlled within the range of 3.7-5.3 meters;

4.2 Water Environment

Measuring the width of the river at the construction site (the narrowest distance and the widest distance) and the construction requirements such as the expected excavation height, excavation depth, excavation distance, etc., exploring factors such as the depth of the river water, the material on the river bed and water flow speed; for some narrow river channels, canals or waterways, etc., generally, 7-8 tons of small water excavation is more suitable;

4.3 Construction Purposes

Evaluating the functional role of the amphibious excavator equipment in the entire construction project, whether it is a leading role or an auxiliary construction; whether it is a phased project or a long-term project; if it is only used for a short term, it can be considered for local rental; if it is used for a long time and may be used for different types of construction projects, then it need to be considered in the long-term and comprehensively; of course, if the project is no longer used after the end of the project, renting the amphibious excavator to other customers in need is also a good choice;

4.4 Working Range And Bucket Capacity Requirements

Extended/Long Reach Arm: In most cases, the amphibious excavator needs to extend the working device, which is what so-called the extended arm. This is because the pontoon undercarriage of the amphibious excavator is larger in size than the crawler excavator, which determines the standard boom needs to be modified to be long reach boom in order to obtain a longer and farther excavation distance;

Bucket: Since we have lengthened the working device(long reach boom), this requires amphibious excavators require a smaller bucket capacity than crawler excavators; on the other hand, due to the different construction environments, the material dug by crawler excavators is usually heavy material such as dry soil and ore; and amphibious excavators are generally constructed in rivers, lakes, seas and other water environments, and the excavated materials are all silt, sediment mixture or half water and half mud materials, so it requires less bucket capacity; We can provide you a wide range of buckets for optional.

4.5 Excavator Model Owned By Customers

Economy: Amphibious excavators are a type of excavator, only the undercarriage structure has changed. If you want to have an amphibious excavator, you can use it for modification; Most of the excavator models in the market can be modified, and we’re able to provide a lot of convenience and technical support for customers to modify amphibious excavators because we have built strong excavators database;

Return on investment: Due to overcapacity, economic downturn, and other reasons, traditional crawler excavators are already in a state of oversupply, and the economic rate of return has become very low; but after being converted into amphibious excavators, not only can waste be turned into treasure, the economic rate of return is also 2-3 times that of traditional crawler excavators, why not? A considerable part of our customer base will choose to use or buy a second-hand excavator to convert it into an amphibious excavator;

4.6 Project Budget;

Last, of course, and most importantly, is the budget; it determines the price of the amphibious excavator you can afford, if you want to know the quotation about the amphibious excavator, you can contact us through this page, We will plan the most economical and reasonable budget solution for you;

5. When Do You Need To Add Side Pontoons

Compared with the main undercarriage, the side buoyancy pontoon has a relatively simple structure and a cheaper price. Its main function is to provide buoyancy for the whole vehicle to ensure that the amphibious excavator can pass through safely no matter how deep the water is. If the amphibious excavator equipment is transferred from one construction site to another, you can consider adding a side floating pontoon, which can be slowly rowed on water and land by extending the arm. Of course, we can also add external auxiliary devices to push it forward, such as a thruster; After the side pontoon is installed, it can perform some simple constructions such as salvaging aquatic plants, cleaning up river surface garbage, etc.; but because it completely floats on the water surface, it is not suitable for heavy construction work, as it’s easy to shake and the construction efficiency is low;

6. Do I Need To Buy Positioning Piles(Spuds)?

As we have mentioned above, it is not recommended for the equipment to carry out heavy construction in deep water areas when only the side pontoon is added, especially when there is a certain water flow speed, the amphibious excavator may float with it; For stable construction at a construction site, it is very necessary to increase the pile device, which can ensure the stable construction of the amphibious excavator in a working environment of about 2-4 meters of water depth, and 4 fully automatic hydraulic positioning piles are stationed behind the bottom of the water. , the whole construction equipment will form a square working platform with a length and width of 8*8 meters, which enables the loading upper working device to rotate 360°safety; But it seems very useless in shallow water, and helpless in deep water;

For the positioning pile device, we provide two pile solutions for customers to choose from: for small amphibious excavators such as 7 tons or 13 tons, we can use mechanical piles, which are cheaper and more flexible and convenient to use; for 20 tons or above excavator models, we recommend fully automatic hydraulic positioning piles, which can operate all piles on the cab control panel, which is convenient and fast, and has more functions and better stability;

7. Attachments Optional

Like traditional crawler excavators, amphibious excavators can be used with various types of attachments, such as water grass buckets, cutter suction pump/dredging pump, pile drivers, quick change, wood clamps, and screening buckets.